1 Hour Delivery Window*

1 Hour Delivery Window*

Gift Ideas

Gift Ideas

Our Reviews

Our Reviews

-

Add the product to your basket

-

Click on 'Your Basket' and choose the option to Checkout

-

Enter your details and select the Band 10 'Click & Collect From Store' option from the Delivery Address screen

-

We will contact you to confirm when the goods are ready to collect*

-

Visit our store with your order confirmation or quote your order reference number to collect your order and pay for your goods in store (Please pay by card if possible).

*Please note some items including large machinery is not kept on site, and will not be available to collect same day

This item is delivered direct from the manufacturer so is subject to being in stock with them. Should the item not be in stock with the manufacturer, you will be contacted either by telephone or email at the earliest opportunity (during trading hours 8.30am-5.30pm Mon-Sat).

It will not be available for same day collection if you place a Click & Collect. You will be notified by phone or email when item is ready to collect.

The product is typically available for dispatch or Click & Collect from our Twickenham Superstore within the time quoted on the individual product page, depending on the specific item and availability with the supplier. These are subject to change.

You will be notified by our sales team of a more accurate delivery date at the earliest opportunity when you place the order (during trading hours 8.30am-5.30pm Mon-Sat).

If you would like more specific information please contact us on sales@dm-tools.co.uk or telephone: 020 8892 3813

You can also click on this item to receive an email notification as soon as the item comes back into stock.

You may also contact us directly on sales@dm-tools.co.uk or by phone on 020 8892 3813 to check when the item is expected back in stock.

Please note: In the unlikely event that the item is over-sold or becomes unavailable whilst in your basket or during your check-out process, we will notify you either by telephone or email at the earliest opportunity (during trading hours 8.30am-5.30pm Mon-Sat)

-1_520x470_100x100.jpg)

-1_520x470.jpg)

-1_520x470_100x100.jpg)

Record Power 50002 Essential Carving Collection - 5 Piece

Ready For Despatch

LOGIN TO ADD FAVOURITES

LOGIN TO ADD FAVOURITES-1_520x470.jpg)

Ready For Despatch

Record Power 50002 Essential Carving Collection - 5 Piece

Create beautiful patterns and designs with this 5-piece Carving by Numbers tool set.

Simply match your numbered carving tools to the step-by-step guidance or create decorations and gifts of your own.

The Essential Collection of 5 carving tool profiles match the step-by-step education in the Woodcarving by Numbers book.

You will also have online access to a growing educational resource including:

- Woodcarving by Numbers Book

- Foundation Skills DVD

- Plans and Projects

- Video Tutorials

- Over 3,000 projects and design ideas

5 Chromium-vanadium alloy steel Carving tools, featuring the unique Carving by Numbers referencing system.

Check out the Carving by Numbers website: carvingbynumbers.com for more information, tips, tutorials, videos and more...

Technical details

Chromium-vanadium alloy steel offers enhanced durability and edge retention over standard carbon steel. Hardened to around RC60 on the Rockwell scale.

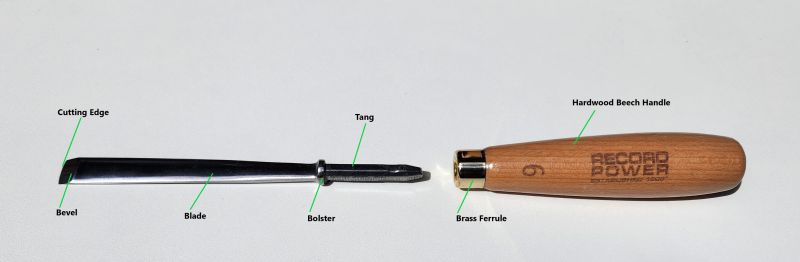

Hardwood beech handles are fitted with a brass ferule and feature the unique number referencing system that partners with the online step-by-step educational resource.

This range of carving tools have been manufactured by Record Power, as a companion range for the Carving by Numbers educational series, created by professional British woodcarver Mike Davies.

The handle is turned from European Beech, a premium grade hardwood with a dense grain. This style of handle is suitable for fine and delicate carvings, or it can be struck with a mallet for heavier sculpting work.

- Handle Length to blade joint is 120mm (4.72”)

- Handle diameter at widest point is 30mm (1.18”)

The blades are manufactured from Chromium-vanadium alloy steel, offering enhanced durability and edge retention over standard carbon steel. Each blade is hardened to around RC60 on the Rockwell Scale.

The blade comprises of the cutting edge formed by a bevel, and the length of steel between the cutting edge to the handle is referred to as the blade. There is a steel bolster at the top of the blade where it meets the handle. The steel then continues beyond the bolster into the handle, and this component is referred to as the tang.

Average Blade Length from cutting edge to the bolster, where it meets the handle joint, is 115mm (4.53”)

Average tool length from tip of handle to cutting edge is 235mm (9.25”)

A brass ring, commonly known as a ferrule, is located at the connection point between the handle and blade. This allows the tang of the blade to be driven into the handle under pressure during manufacture, and prevents the timber handle from splitting. It also reinforces the joint when the tool is used for heavy sculpting work with a mallet.

Ferrule dimensions are 12.5mm long (0.5”)

Ferrule diameter is 12.5mm (0.5”)

The tang is the length of steel that is fitted into the handle. The tang is inserted into the handle under pressure, and the brass ferrule prevents the hardwood beech handle from splitting at the joint.

The length of the tang averages 45mm (1.77”) and is a substantial 7mm (0.28”)in diameter. The tang is designed and manufactured with parallel sides, rather than tapered, to ensure maximum surface contact with the handle.

Contact Us

Contact Us 020 8892 3813

020 8892 3813

-1.jpg)

In Stock

In Stock

Find Us

Find Us MON - SAT 08:30 - 17:30

MON - SAT 08:30 - 17:30 020 8892 3813

020 8892 3813